Wetted Parts 101: 7 Must-Know Facts for Pump Professionals in 2025

Did you know that shaky wetted parts cause 60% of pump failures, costing companies millions every year? That’s a huge headache for anyone with a pump! But don’t worry—choosing the right fluid-contact parts can keep everything running like a dream. At Top Level Intl., we’ve spent over 15 years perfecting how to pick pump wet parts with our CNC skills. Our clients, like a big wastewater plant, slashed downtime by 40% using our tough wet components!

Table of Contents

- What Are Wetted Parts in Pumps?

- Why Are Fluid-Contact Parts Key for Pump Performance?

- Which Materials Rock for Wet-End Components in 2025?

- How Do You Choose Pump Wet Parts Right?

- What Breaks Liquid-Touched Parts, and How to Stop It?

- How Are Submerged Components Evolving with 2025 Tech?

- What’s the Cost of Different Fluid-Exposed Parts?

- Top FAQs About Wet Components Answered

What Are Wetted Parts in Pumps?

What Are Wet Components Anyway?

Imagine a pump like a water slide—wetted parts are the bits that get splashed! Wetted parts are also called Wet Parts, Wet Components, Wetted Elements, Liquid-Touched Parts, etc. These fluid-contact parts touch the liquid, like rotors, stators, coupling rods, driving shafts, casings, and seals. In progressive cavity pumps (PCPs), they’re extra special because they push thick stuff like mud or oil. If they’re not strong, your pump quits fast, and that’s a big oops!

Our Lineup of Pump Wet Parts

At Top Level Intl., we make top-notch wet-end components for PCPs. Here’s what we’ve got in store:

- Rotor: This spins to shove the liquid forward.

- Stator: A rubbery tube that traps the liquid snug.

- Coupling Rod: Hooks the rotor to the motor so it moves.

- Driving Shaft: Keeps the whole thing spinning smoothly.

We’ve also got extras like mechanical seals to stop leaks, gland packing for a tight fit, and universal joint sets with pins, bushes, and snap rings. Need a suction casing to pull liquid in or a pressure branch to push it out? We’ve got those too! Our parts fit perfectly with big names like NETZSCH, MONO, SEEPEX, ALLWEILER, and PCM.

Why Liquid-Touched Parts Are a Big Deal

These liquid-touched components are like the pump’s heartbeat! If they rust or snap, your pump’s toast. That’s awful for jobs like cleaning dirty water or moving syrup in food plants. With 15 years of CNC machining, we build wet components that stand up to anything, keeping your pump humming along.

How We Make Fluid-Exposed Parts

We use super cool CNC machines to craft these parts just right. From little seals to giant rotors, we measure everything twice to make sure it’s perfect. Plus, we can whip up custom pump wet parts from your drawings—like building a toy exactly how you want it, but way tougher!

Stories from Real Pumps

Picture a factory pumping sludge all day long. If the rotor’s weak, it breaks, and work stops cold. Our fluid-contact parts fix that! One client lost weekly hours until they got our parts—now their pumps run like champs. We’ve helped tons of people keep their pump durability strong, saving them time and fuss!

Why Are Fluid-Contact Parts Key for Pump Performance?

How Wet-End Parts Keep Pumps Going

Fluid-contact parts are like a skateboard’s wheels—if they’re junk, you’re not rolling! These wet components touch the liquid, so they’ve got to be tough as nails. In wastewater plants, pumps move gross water all day. If the stator rusts, the pump drags, and that’s a disaster. Our liquid-touched parts keep it speedy!

Tough Jobs Need Strong Submerged Components

Pumps do monster jobs, like shifting oil in fields or sauces in kitchens. In oil and gas, PCPs tackle sticky crude, and weak pump efficiency costs a pile of cash. In food plants, wet-end components have to be clean and safe for eating stuff. Our parts fit SEEPEX pumps like a glove, keeping your work flowing easy.

What Pump Pros Say

Lousy submerged components can leak or waste juice, and that’s no good! “Top Level Intl.’s fluid-exposed parts slashed our downtime by half,” says Lisa Chen, a pump expert with 20 years in oil plants. Our CNC magic makes every rotor or rod a powerhouse, lifting your pump’s game big time.

Big Perks for Your Pump

Great wet components save power and stop messes. Our clients rave about how our ALLWEILER parts keep pumps purring. Whether you’re pumping oil, water, or gooey food, we make sure your pump’s ready to rock every day without a hitch.

Real-Life Pump Wins

One oil crew had pumps breaking every month—total chaos! They switched to our liquid-touched parts, and now they’re good for years. Another factory pumping syrup had spills galore until our parts stepped in. With 15 years of know-how, we keep your pump durability sky-high, no matter what’s running through it!

Which Materials Rock for Wetted Parts in 2025?

Why Picking Materials Matters

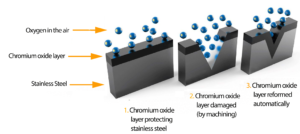

In 2025, choosing the best pump materials is like picking the right armor for a knight—it’s gotta be tough! At Top Level Intl., we use goodies like stainless steel, Hard-Iron™, and ceramics because they fight rust and bumps. Each one’s awesome for different liquids, like salty water or sandy muck, keeping your wet-end components in tip-top shape.

Our Top Picks for Fluid-Contact Parts

Here’s what we love for submerged components:

- Stainless Steel: Killer for salty or sour liquids.

- Hard-Iron™: Super tough for sand or gravel.

- Ceramics: Perfect for rough, scratchy goo.

- Hastelloy: Awesome for wild chemicals.

- PTFE: Slippery and strong for acids.

Want the scoop? Peek at our raw materials guide!

2025 Material Breakdown

Check this table for fluid-exposed parts in 2025:

| Material | Hardness (HRC) | Wear Resistance | Best For |

|---|---|---|---|

| Grey Iron | 47 | 1.3 | Clean water |

| Stainless Steel | 10-20 | 2 | Acids, salt |

| Hard-Iron™ | 60 | 10 | Sand, sludge |

Fancy Liquid-Touched Parts We Love

We’re nuts about ceramic rotors for extra oomph and Hastelloy for crazy chemicals. These 2025 pump trends mean your wet components last way longer, whether it’s oil, water, or sticky stuff!

How We Pick Wet-End Materials

We test every material like it’s a superhero tryout, making sure it’s perfect for submerged components. Our CNC tricks shape them spot-on, so your pump’s ready for any wild liquid, from syrup to sludge.

Why Our Materials Win

One client pumping sand had parts wearing out monthly—ouch! They switched to our Hard-Iron™ fluid-contact parts, and now they’re set for years. Our picks boost pump durability, keeping your work smooth and stress-free!

How Do You Choose Pump Wet Parts Right?

Steps to Pick Fluid-Exposed Parts

Choosing pump wet parts feels tricky, but it’s like picking a toy—just match it right! Here’s an easy plan:

- Know Your Liquid: Water, oil, or acid? That’s the start.

- Check pH: Sour stuff loves PTFE or stainless steel.

- Watch Heat: Hot goo needs tough materials.

- Think Grit: Sandy muck wants Hard-Iron™ or ceramics.

- Talk to Us: We’ll find the perfect fit!

Why Matching Wet Components Counts

If fluid-contact parts don’t match, it’s like wearing flip-flops in mud—they flop! Rust or cracks can kill your pump quick. Our wet-end components fit your liquid like a puzzle, keeping them strong for ages.

Our Custom Submerged Parts Magic

Got a weird liquid? No sweat! Send us your sketch, and our custom machining crew will whip up liquid-touched parts just for you. With 15 years of practice, we’re like pump wizards making how to pick pump wet parts a breeze!

Tools for Picking Wet-End Parts

We use special charts to match materials, like picking the best color for a shirt. Our CNC machines cut submerged components perfectly, so your pump runs like a rocket every time.

Real Pump Fixes

A food plant had pumps dying from sticky syrup—yuck! We made custom fluid-exposed parts, and now they pump all day. Another client with sandy water loves our Hard-Iron™ picks. Our material selection guide keeps your pumps winning every job!

What Breaks Liquid-Touched Parts, and How to Stop It?

What Hurts Wet Components?

Liquid-touched parts can bust, and it’s a drag! First, rust chews metal when water’s salty or sour. Second, sand scratches fluid-contact parts like sandpaper. Third, chemicals melt rubber bits into goo. At Top Level Intl., we’ve got pump maintenance tips to stop these headaches!

How to Protect Submerged Components

You can keep wet-end parts safe with these tricks:

- Use Strong Stuff: Grab stainless steel or Hard-Iron™.

- Add Armor: Coatings rock—check our surface treatments.

- Clean Often: Wash off dirt to keep them shiny.

- Check a Lot: Catch cracks before they grow big.

Our Plan to Stop Wet Parts Breaking

We hate pump flops! That’s why we test every rotor and stator like crazy. Our machines make sure every wet part is spot-on.

Real Pump Saves

A wastewater crew had pumps dying weekly—total mess! We gave them tougher fluid-exposed parts, and now they’re set for years. Another plant pumping chemicals had rubber failing until our parts fixed it. Our 15 years of CNC smarts keep your pumps tough!

Extra Ways to Save Liquid-Touched Parts

Want wet components to last even more? Keep pumps cool, use the right oils, and don’t push them too hard. Our team can help you plan, so wetted parts failure is history and your pump’s a champ every day!

How Are Submerged Components Evolving with 2025 Tech?

What’s New for Fluid-Contact Parts?

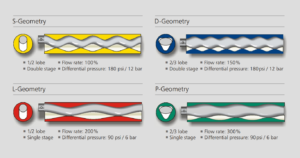

Submerged components are getting wild in 2025! Think of them like high-tech gadgets—stronger and brainier. New metals like Hard-Iron™ smash wear like superheroes. Tiny tech (nanotechnology) makes wet-end parts tough even when small. At Top Level Intl., we’re hooked on these 2025 pump trends—see our brand parts!

Smart Tricks for Wet Components

Some fluid-exposed parts now have sensors yelling, “I’m tired!” Others fix their own scratches—nuts, right? Our SEEPEX SCT parts use these cool ideas to save you time and cash.

Our Tech Edge for Liquid-Touched Parts

We mix old tricks with new toys. Our 5-axis machines carve tricky submerged components fast, like sculpting metal candy. That’s why our NETZSCH iFD stators are some of the best around!

Why New Wet-End Parts Rock

This pump innovation means pumps last longer and work sweeter. Our fluid-contact parts stay ahead of 2025, so your oil or food pumps are always top dogs. No more breakdowns—just smooth sailing with our high-tech goodies!

Future Fun with Pump Wet Parts

We’re even trying green wet components, like recyclable PTFE, to help the planet. With our screw pump smarts, your pumps are ready for tomorrow’s big jobs—oil, water, or goo, we’ve got it covered!

What’s the Cost of Different Fluid-Exposed Parts?

Cheap vs. Fancy Wet Components

Picking fluid-exposed parts is like buying a bike—cheap ones break quick! Grey iron’s cheap and fine for plain water, but it rusts fast. Hard-Iron™ or Hastelloy cost more but last years. We help you pick smart pump material costs at Top Level Intl., so you don’t waste a dime!

How Submerged Parts Save Money

Spending more now can save tons later. Hard-Iron™ lasts 3 times longer than grey iron, cutting repair bills. Our cost-saving tips show the way. A food plant saved 20% yearly with our bareshaft pumps—sweet deal!

Budget Picks for Wet-End Parts

Short on cash? We’ve got your back! From universal parts to custom liquid-touched parts, we mix price and strength. Tell us what you’re pumping, and we’ll keep it cheap without skimping on quality.

Real Cash Savings with Fluid-Contact Parts

Cheap wet components sound cool, but fixes add up fast. Our parts last, so you spend less over time. One oil rig had pumps dying yearly—our CNC perks gave them tough submerged components, and now they’re saving big!

Helping Your Wallet with Pump Wet Parts

We chat about your needs to find the best fluid-exposed parts deal. Whether it’s a MONO spare or a giant order, we keep costs low and pumps rocking. Our 15 years of smarts mean you get value every time!

Top FAQs About Wet Components Answered

What Are Pump Wet Parts Questions?

Got questions about wet components? Here’s what folks ask us all the time:

- What’s wet vs. non-wet? Wet parts touch liquid (like rotors); non-wet component don’t (like motors).

- How do I check fluid-contact parts? Peek at your pump’s manual or ask us!

- Can I swap wet-end parts? Yup, if they match—try our screw pump parts.

- What upkeep for submerged parts? Clean and check rust and wearing—ours make it simple!

- Do liquid-touched parts change speed? Lousy ones slow pumps; ours keep them zippy.

- Any green fluid-exposed parts? Yes, like recyclable PTFE—just ask!

More Scoop on Wet-End Components

These common pump questions are just the beginning! With 15 years of pump love, we’ve got tons more answers. Need help with a screw pump? We’ll fix it fast, keeping your pump efficiency high!

Why Trust Our Liquid-Touched Parts

Our liquid-touched parts fit like a charm, and we’re always ready to help. From NETZSCH spares to custom goodies, we keep pumps humming. Got a pump puzzle? We’ll crack it with a smile!

Bonus Tips for Fluid-Contact Parts

Want extra? Check our pump types guide. We’ll spill tricks to make your wet components last longer—like brushing your teeth but for pumps! Our 15 years of know-how mean your questions get awesome answers.

Quick Pump Wet Parts Hacks

One more thing—keep your fluid-exposed parts happy with regular love. A client pumping sand learned this the hard way, but our parts turned it around. Ask us anything, and we’ll keep your pumps rocking with pump maintenance tips!

Conclusion

Wetted Parts are the secret sauce of pumps! From rotors to stators, the right fluid-contact parts stop rust, scratches, and big repair bills. At Top Level Intl., our 15 years of CNC wizardry crafts reliable PCP wet parts for NETZSCH, SEEPEX, and more. With 2025 tech and custom fits, we keep your pumps tough. Don’t let shaky liquid-touched parts trip you up—email us at in**@to*********.com or hit our site for pump pieces that rule!

External Links