Types of Pumps

There are many different types of pumps. Pumps are used in a wide range of industrial and residential applications. Pumping equipment is extremely diverse, varying in type, size and materials of construction. The pump medium is usually liquid. However, many pump designs can handle solids in the forms of suspension and trained or dissolved gas, paper pulp, mud, slurries, tars, and other exotic that at least by appearance do not resemble liquids.

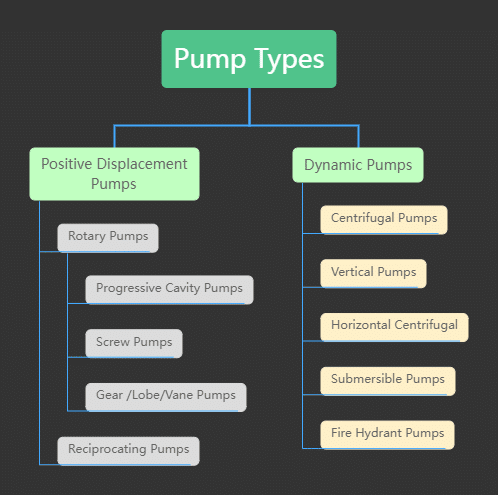

As regards the classification of pumps, Pumps are basically divided into two fundamental types: dynamic pumps and positive displacement pumps, based on the manner in which they transmit energy to the pumped media.

- Types of Pumps

- What are dynamic pumps? How do the dynamic pumps work?

- What are positive displacement pumps? How do the positive displacement pumps work?

- Is a progressing cavity pump a rotary type of pump?

- What other terms do progressing cavity pumps have?

- The applications of progressive cavity pumps?

- What Makes Progressive Cavity Pumps So Special?

What are dynamic pumps? How do the dynamic pumps work?

Dynamic pumps are also known as kinetic pumps. The dynamic displacement, a centrifugal force of the rotating element called an impeller, import velocity energy to the fluid, moving the fluid from pump suction to the discharge.

On the other hand, positive displacement uses the reciprocating action of one or several pistons or the squeezing action of meshing gears, lobes or other moving bodies to displace the fluid from one area into another.

What are positive displacement pumps? How do the positive displacement pumps work?

Positive displacement pumps are divided into two broad classifications: Reciprocating and rotary pumps.

For reciprocating pumps, the reciprocating action of the pump causes a plunger or piston or diaphragm to move back and forward which in turn causes the liquid to flow into and out of the pump. For rotary pumps, the liquid is drawn into the suction nozzle through a set of gears and lobes.

Is a progressing cavity pump a rotary type of pump?

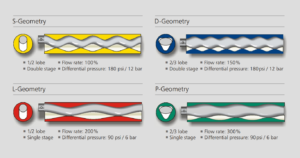

Progressing cavity pump (PC pump) is a rotary type of pump. PC pump is not usually used in the same way or considered to be the same as other rotary positive displacement pumps. The progressing cavity pump was designed as a combination of a rotary pump and a piston pump. It represents an integration of the specific advantages of both types of pump constructions.

What other terms do progressing cavity pumps have?

The other terms for progressing cavity pumps are cavity pumps, progg cavity pumps and PC pumps. Progressive cavity pumps are mostly used in wastewater treatment plants. It handled thickened and treat sludge transfer and polymer dosing then petroleum production.

The applications of progressive cavity pumps?

The pump is used in cutting transfer, drilling mud transfer and recovery, separator feed and crude oil transfer. Being food and beverage applications, progressing cavity pumps can be designed to reduce the risk of contamination. The pump is also used in sewage slurry and sludge pumping in the paper and pulp industry. The pump is used in pole transfer recycled paper transfer and filler transfer.

What Makes Progressive Cavity Pumps So Special?

What makes progressive cavity pumps so special? Why do they preferable by people? Let’s check the advantages of this type of positive displacement pump.

Advantages of progressive cavity pumps

- Good for solids handling and can also handle air-entrained, multiphase and abrasive liquids.

- Excellent choice for high-viscosity applications;

- Offer low net positive suction head required self-primer pump;

- Offer high accuracy as a metering pump;

- Reversible direction/ bi-directionally. The pump can be operated in either direction and the suction becomes the discharge and vice versa;

- Can be operated vertically.

Disadvantages of progressive cavity pumps

Certainly, progressive cavity pumps are not perfect in some factors. Then we should be aware of the disadvantages of PC pumps below.

- Due to the interference fit between the stator and rotor, a fluid film is required to lubricate the sliding (contacting) surfaces. Cavity pumps are not allowed to dry run.

- Low speed also requires VFD (variable frequency drives) and gear reducers.

- Low-viscosity fluids tend to slip by the rotor to stator fits and the pump will be less efficient.

- With highly viscous fluids there is a pump speed above which the fluid will not flow fast enough into the pump

Thanks for reading this post! We are a reliable supplier of after-market spare parts for single progressive cavity pumps. Mainly provide the replacement universal parts for NETZSCH PUMPS, MONO PUMPS, SEEPEX PUMPS and ALLWEILER Pumps. The generic parts we supplied can highly match the original pump parts and be with equivalent service life. They are high-quality replacement PC Pump parts. Should you still have further questions on the single progressive cavity pumps or PC pump parts, please feel free to EMAIL US or WhatsApp us for further suggestions or recommendations.

1 thought on “Types of Pumps and Their Working Principles”

Pingback: iFD-Stator for NETZSCH Pumps: Save Time & Money